Product Search

Quickly find the products you need.

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

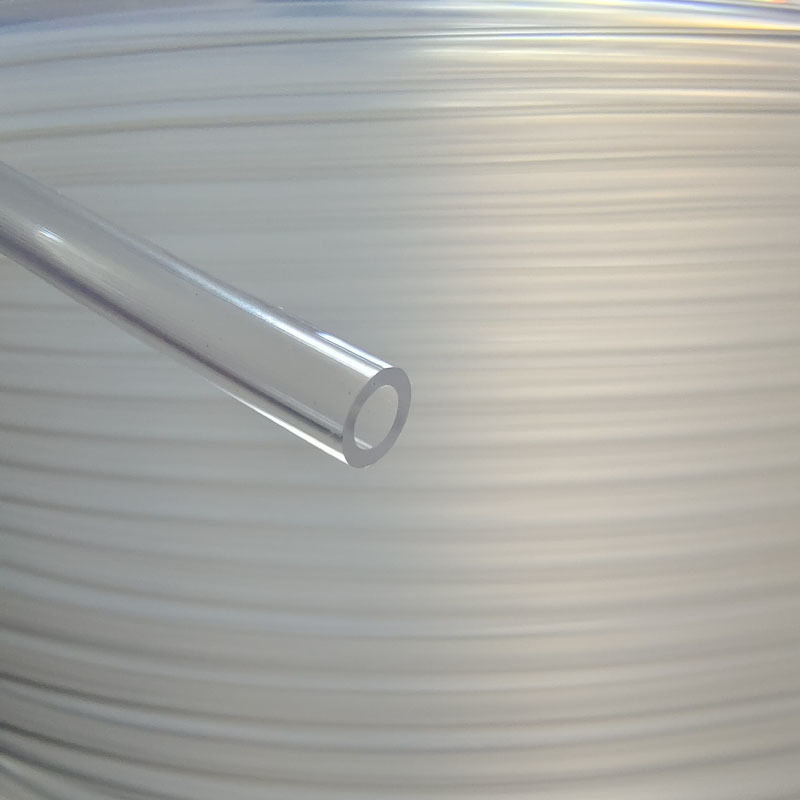

PTFE

- Commodity name: PTFE

- Product Description

-

Polytetrafluoroethylene (PTFE)

PTFE, commonly known as plastic king, is a polymer made of tetrafluoroethylene monomer polymerization. It is a transparent or opaque wax similar to PE, with a density of 2.2g/cm3 and a water absorption rate of less than 0.01%. Its chemical structure is similar to PE, except that all hydrogen atoms in polyethylene are replaced by fluorine atoms. Stable performance, its excellent chemical resistance.

Application of anti-corrosion performance

PTFE material with its excellent corrosion resistance, has become the main corrosion resistant materials in petroleum, chemical, textile and other industries. Its specific applications include: conveying pipes, exhaust pipes, steam pipes for conveying corrosive gases, high-pressure oil pipes for steel rolling mills, Senior high school low-pressure pipes for aircraft hydraulic systems and cold-pressure systems, rectification towers, heat exchangers, kettles, towers, and tanks Lining, valves and other chemical equipment.

The performance of the seal has a great influence on the efficiency and performance of the whole machine equipment. PTFE material has the characteristics of corrosion resistance, aging resistance, low friction coefficient and non-stick, wide temperature range, and good elasticity, which makes it very suitable for manufacturing seals with high corrosion resistance requirements and the operating temperature is higher than 100 ℃. Such as machine, heat exchanger, high pressure vessel, large diameter vessel, valve, pump groove flange seal, glass reaction pot, flat flange, large diameter flange seal, shaft, piston rod, valve rod, worm gear pump, pull rod seal, etc.

Application of low friction performance in load

Because the friction part of some equipment should not be lubricated, for example, in the occasions where lubricating grease will be dissolved by solvent and fail, or in the fields of papermaking, pharmacy, food, textile and other industrial products, it is necessary to avoid lubricating oil contamination, which makes the filled PTFE material become the most ideal material for oil-free lubrication (direct load bearing) of mechanical equipment parts. This is because the friction coefficient of this material is the lowest among the known solid materials. Its specific uses include bearings for chemical equipment, paper machinery, agricultural machinery, as a piston ring, machine tool guide, guide ring.

Warehouse

Workshop

Key words:

Get Quote