Product Search

Quickly find the products you need.

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

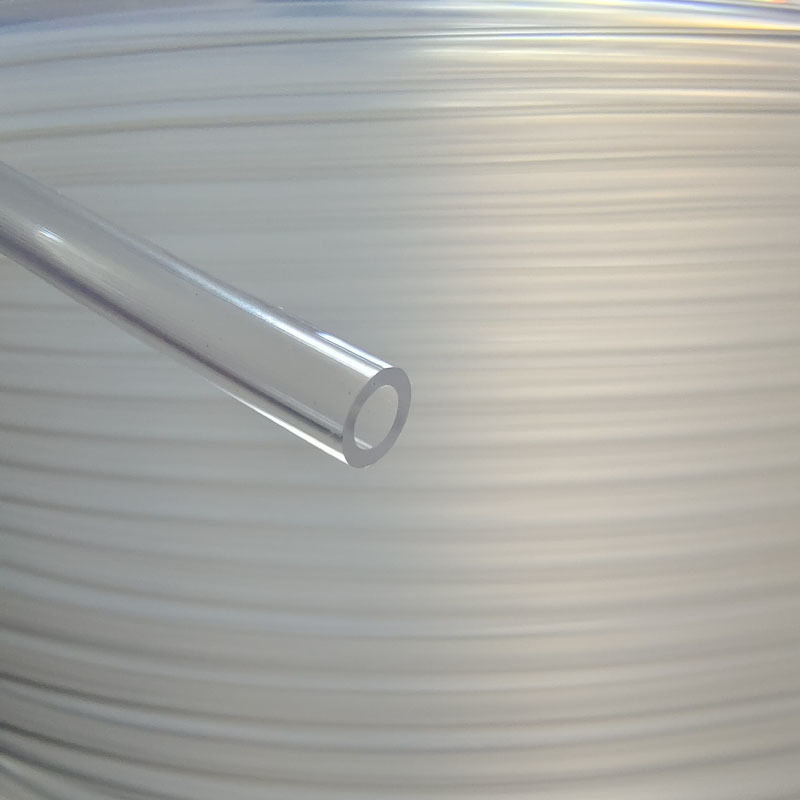

PFA Extrusion Tube Products

- Commodity name: PFA Extrusion Tube Products

- Product Description

-

PFA is a fluoropolymer resin or a fluorocarbon. Fluorocarbons are those polymers in which the carbon atoms of the polymer are bonded to the fluorine atoms surrounding the carbon backbone of the PFA polymer. PFA is a fluorinated polymer that has the same chemical resistance and high temperature properties as PTFE, and has a much lower porosity than PTFE, which makes it translucent instead of opaque white, and has higher mechanical strength. PFA can be extruded into pipe or tubing, or injection molded into fittings for applications up to 150°C(300 °F). P FA is the best choice for fluoropolymer tubing.

Molecular formula

-[(CF2CF2)nCF2CFm]x|0|C3F7

learning and heat resistance

The carbon-fluorine single bond is one of the strongest single bonds known, causing PFA to be chemically inert in nature and is responsible for the excellent thermal properties of PFA.

In general, PFA is inert to almost all chemicals. It is chemically resistant to strong minerals and oxidizing acids, alkalis, halogens, metal salt solutions, organic acids and anhydrides. Aromatic and aliphatic hydrocarbons, alcohols, aldehydes, ketones, ethers, amines, esters, chlorinated compounds and commonly used cleaning solvents have little effect. PFA is not inert to molten alkali metals, fluorine at high temperatures, and certain complex halogenated compounds at high temperatures and pressures.

creep strength

Of all the fluorocarbon materials, PFA exhibits the highest creep resistance.

absorption and penetration

The absorption rate of PFA is very low, and there is little chemical reaction between the resin and other substances.

Workshop

Key words:

Get Quote